NanoTec™/NanoCleave™

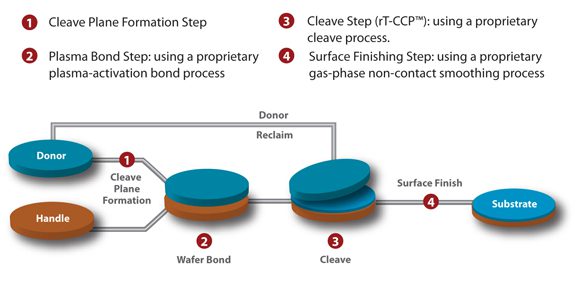

The NanoTec process is best understood as a very accurate thin-film layer-transfer process. The layer to be transferred is chosen from one wafer or substrate (the "donor" wafer), while the base wafer or support may be selected from another material (the "handle" wafer).

The NanoCleave® process uses an internal compressive strain layer to guide a fracture across the substrate to release the overlying film from the donor substrate. This processed donor wafer is then bonded onto the handle wafer to form a wafer assembly. To separate the donor layer from the rest of the donor wafer, the unique rT-CCP™ separation step cleaves the wafer assembly at the stressed region, thereby releasing the layer onto the handle substrate. By keeping all steps at low temperatures, the process has the added advantage of opening new applications, such as dissimilar material layer transfer.

Layer Transfer Animated Slideshow (885KB PPS Format)

There are four key steps in the NanoTec process. These are: